Cathodic protection (CP) is a technique used to control the corrosion of a metal surface by making it the cathodic side of an electrochemical cell.

This can be achieved by employing two distinct types of cathodic protection: passive cathodic protection and impressed current cathodic protection.

Passive cathodic protection

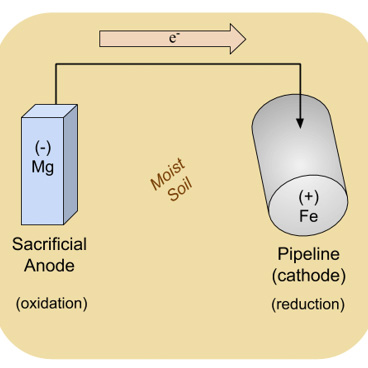

In passive cathodic protection system, the sacrificial anode is connected directly or indirectly to the metal to be protected. The potential difference between the two dissimilar metals generates adequate electricity to form an electrochemical cell and drive galvanic or bimetallic corrosion.

This type of protection is commonly used in the oil and gas industry to protect the structural steel structure/small underground vessels/pipelines.

Impressed current cathodic protection (ICCP)

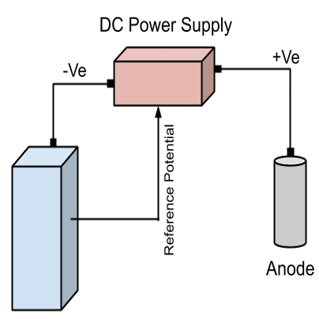

In large structures & underground/mounded vessels , it may not be feasible to use passive cathodic protection methods. The number of sacrificial anodes required to deliver enough current to provide adequate protection can either be unrealistic or impractical. To address this, an external power source is used to assist in driving the electrochemical reactions. This technique is known as impressed current cathodic protection system (ICCP).